| Name | Material | Colour | Texture |

| As-machined | All material | N/A | N/A |

| Bead Blasting(Sandblasting) | All material | N/A | Matte |

| Anodizing | Aluminum | Black, Silver, Red, Blue etc | Matte and Smooth |

| Polishing | All material | N/A | Smooth, Glossy |

| Power Coating | Aluminum, SS, steel | Black, White or Custom | Matte, Glossy, Semi-Glossy |

| Zinc Plated | SS, Steel | Black, Clear | Matte |

| Black Oxide | SS, Steel | Black | Smooth |

| Black E-coat | SS, Steel | Black | Smooth |

| Painting | All material | Any Pantone or RAL Colour | Matte, Smooth, Glossy |

| Silk Screen | All material | Custom | Custom |

| Electroplating | ABS, Aluminum, Copper, steel, stainless steel | Gold, silver, nickel, copper, brass | Smooth, Glossy |

Check our our quality-focused custom parts made using advanced surface finishing techniques.

Check our our quality-focused custom parts made using advanced surface finishing techniques.Silk Screen offers a cost-effective solution for incorporating logos or customized text, frequently used for product identification in full-scale production.

The standard finish for our parts, the "as machined" finish, with a surface roughness of 3.2 μm, which removes sharp edges and burss parts cleanly.

Bead blasting involves the forceful projection, often at high pressure, of a stream of abrasive media against a surface, effectively eliminating unwanted coatings and surface impurities.

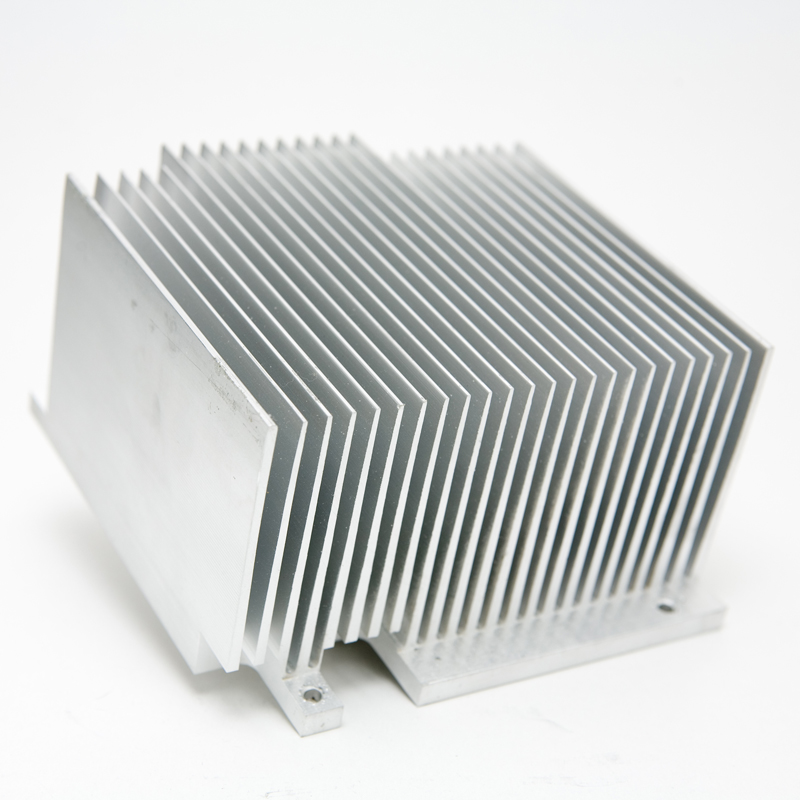

For long-term part preservation, our anodizing process offers exceptional resistance to corrosion and wear. Additionally, it serves as an ideal surface treatment for painting and priming, while also enhancing the overall aesthetic appeal.

Our polishing processes cover a range from Ra 0.8 to Ra 0.1, utilizing abrasive materials to delicately modify the part's surface shine to meet your specific requirements, whether you desire a glossier or subtler finish.

Through the application of corona discharge, we achieve effective adhesion of the powder coating to the part's surface, resulting in the formation of a robust, wear-resistant layer. This layer typically boasts a thickness that ranges from 50 μm to 150 μm

Electroplated coating preserves part surfaces by utilizing electric currents to reduce metal cations, effectively preventing rust and decay.

A chemical conversion coating used on ferrous metals to create a black, corrosion-resistant finish with enhanced wear resistance and minimal light reflection.

An electrodeposition coating process that imparts a black, corrosion-resistant finish to metal surfaces for enhanced durability and aesthetics.

Painting entails applying a paint layer onto the part's surface. Customizable colors using Pantone references, with finish options spanning matte, gloss, and metallic.

Plying a protective zinc layer to metal surfaces for corrosion resistance and improved aesthetics in various industrial applications.