Top Sheet Metal Fabrication Supplier in China

By:Admin

The company has positioned itself as a one-stop solution for all manufacturing needs, offering a comprehensive suite of services that includes CNC machining, injection molding, sheet metal fabrication, 3D printing, and more. With a strong focus on precision and efficiency, Foxstar has earned a reputation for delivering superior products and exceeding customer expectations.

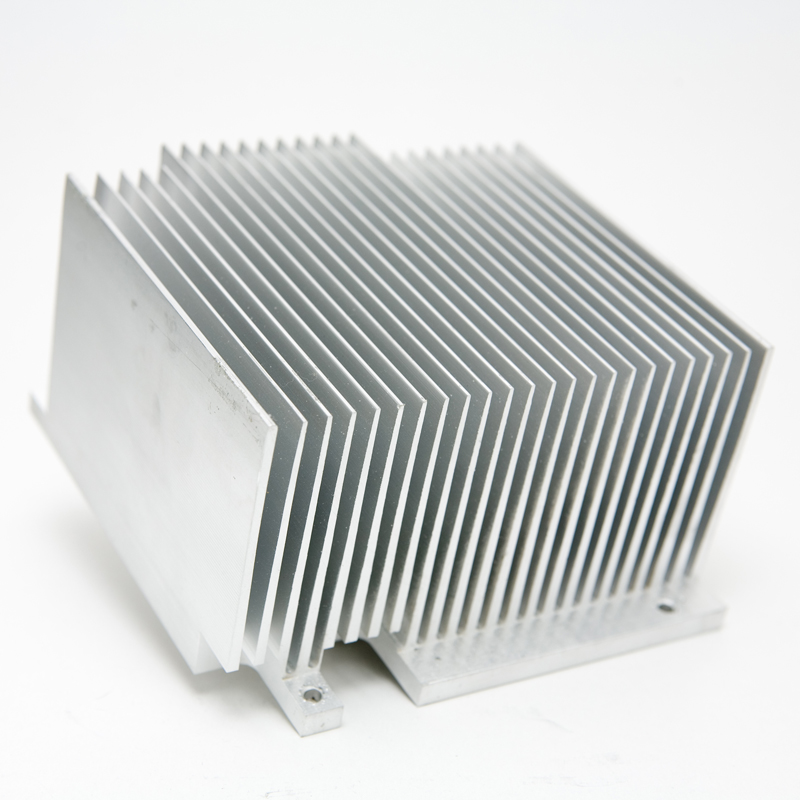

Sheet metal fabrication is one of the key services offered by Foxstar, and the company has invested heavily in state-of-the-art equipment and technology to ensure the highest level of precision and quality. From cutting and bending to welding and finishing, Foxstar's sheet metal fabrication capabilities are second to none. The company works with a variety of materials, including stainless steel, aluminum, and copper, and offers a range of finish options to meet the unique requirements of each project.

In addition to sheet metal fabrication, Foxstar also specializes in CNC machining, leveraging advanced equipment and a team of highly skilled engineers to produce complex and intricate parts with tight tolerances. Whether it's prototyping or high-volume production, Foxstar has the expertise and capabilities to deliver precision-machined components that meet the most demanding specifications.

Furthermore, Foxstar's injection molding capabilities allow the company to produce a wide range of plastic parts for various applications. With a focus on efficiency and cost-effectiveness, Foxstar leverages its expertise in mold design and manufacturing to deliver high-quality injection-molded parts at competitive prices.

The company's 3D printing services further showcase its commitment to innovation and cutting-edge technology. With the ability to produce complex geometries and rapid prototypes, Foxstar's 3D printing capabilities enable clients to bring their designs to life with speed and precision.

Foxstar's dedication to quality and customer satisfaction is evident in its approach to manufacturing. The company's commitment to continuous improvement and innovation has enabled it to stay ahead of the competition and consistently deliver products that exceed industry standards.

Moreover, Foxstar's ability to serve multiple industries, including automotive, aerospace, electronics, and medical, underscores its versatility and adaptability. The company's expertise in working with different materials and understanding the unique requirements of each industry has positioned it as a trusted partner for a wide range of businesses.

With a focus on quality, precision, and efficiency, Foxstar has become a go-to supplier for companies looking for reliable manufacturing solutions. The company's one-stop approach, combined with its comprehensive suite of services, has simplified the manufacturing process for its clients, allowing them to streamline production and bring their products to market faster.

In conclusion, Foxstar's commitment to delivering superior precision and efficiency on every project sets it apart as a leading provider of manufacturing services. With a diverse range of capabilities, the company has positioned itself as a one-stop solution for sheet metal fabrication, CNC machining, injection molding, 3D printing, and more. By serving multiple industries with a variety of materials and finish options, Foxstar has established itself as a trusted partner for clients seeking top-quality products and exceptional service.

Company News & Blog

Understanding the Importance of Die Casting Pressure in Manufacturing Processes

[Headline]: Die Casting Pressure Increases Global Demand for Superior Manufacturing SolutionsIn today's rapidly evolving global manufacturing landscape, the demand for superior precision and efficiency has never been higher. Companies across a multitude of industries are seeking reliable partners who can deliver high-quality products with quick turnaround times. One such company that has been leading the way in this regard is Foxstar, a renowned expert in providing comprehensive manufacturing solutions.With a diverse range of services, including CNC machining, injection molding, sheet metal fabrication, 3D printing, and more, Foxstar has been serving multiple industries with a variety of materials and finish options. Their one-stop approach to manufacturing has garnered attention from companies worldwide.However, one service that has been drawing particular interest in recent times is die casting. The demand for die casting services has been steadily increasing due to its ability to produce complex parts with high levels of accuracy and repeatability. As a result, Foxstar has ramped up its die casting capabilities to meet the growing global demand.Die casting is a versatile process that involves injecting molten metal into a steel mold, or die, under high pressure. This process allows for the creation of precise, high-strength parts with excellent surface finishes. It is particularly well-suited for applications in industries such as automotive, aerospace, consumer electronics, and more.The ability to provide superior die casting services has set Foxstar apart from its competitors. By leveraging their expertise in this area, Foxstar has been able to serve the needs of companies that require complex, high-quality parts in large quantities. This has positioned the company as a valuable partner for businesses looking to streamline their manufacturing processes and achieve superior product quality.One of the key advantages of die casting is its ability to produce parts with tight tolerances and excellent dimensional stability. This level of precision is essential for industries where part-to-part consistency is critical. Additionally, die casting allows for the integration of complex geometries and thin-walled sections, making it an ideal choice for lightweight, yet durable components.Moreover, die casting offers cost-effective solutions for high-volume production. The ability to produce a large number of parts in a short amount of time makes it an attractive option for companies looking to meet demanding production schedules without compromising on quality.Foxstar's commitment to delivering superior die casting services is backed by their state-of-the-art facilities and a team of skilled engineers and technicians. Their comprehensive approach to manufacturing, combined with a relentless focus on quality and efficiency, has earned them a reputation as a trusted partner for companies seeking advanced manufacturing solutions.In addition to die casting, Foxstar's extensive capabilities in CNC machining, injection molding, sheet metal fabrication, and 3D printing further solidify their position as a leading provider of manufacturing services. Their ability to offer a wide range of solutions under one roof simplifies the manufacturing process for their clients, allowing them to benefit from seamless project management and consistent quality across all services.As the global demand for high-quality manufacturing solutions continues to rise, Foxstar remains dedicated to meeting and exceeding the expectations of their clients. By staying at the forefront of technological advancements and continuously improving their services, they are poised to lead the industry in delivering superior precision and efficiency on every project.With die casting pressure increasing across the globe, Foxstar's unwavering commitment to excellence positions them as a go-to partner for companies looking to elevate their manufacturing capabilities and stay ahead in today's competitive market. As they continue to expand their offerings and drive innovation, Foxstar is set to play a pivotal role in shaping the future of manufacturing.

Breathable and durable panting parts now available for purchase

[Company Introduction: XYZ Company is a leading manufacturer of automotive parts, specializing in the production of high-quality panting parts. With advanced technology and a strong commitment to innovation, XYZ Company has established itself as a trusted supplier in the automotive industry.]The demand for panting parts has been on the rise in recent years, driven by the increasing production and sales of vehicles worldwide. As one of the leading manufacturers in this segment, XYZ Company has been at the forefront of meeting this growing demand with its high-quality products and innovative solutions.In a recent announcement, XYZ Company revealed its plan to expand its production capacity for panting parts in order to meet the increasing demand from its customers. The company's decision comes in response to the rising production volumes of vehicles globally and the need for reliable and efficient panting parts to support this growth.With its state-of-the-art manufacturing facilities and cutting-edge technology, XYZ Company is well-positioned to enhance its production capabilities and meet the growing needs of the automotive market. The company's investment in expanding its production capacity for panting parts is a testament to its commitment to providing its customers with high-quality products that meet the highest standards of performance and durability.In addition to its production expansion, XYZ Company has also been focusing on further improving the quality and efficiency of its panting parts through research and development initiatives. By investing in advanced technologies and continuous innovation, the company aims to offer its customers the most reliable and advanced panting parts in the market.XYZ Company's dedication to product excellence and customer satisfaction has earned it a strong reputation in the automotive industry. The company's panting parts are known for their superior quality, precision engineering, and exceptional performance, making them a popular choice among vehicle manufacturers and aftermarket suppliers worldwide.The expansion of XYZ Company's production capacity for panting parts is expected to not only meet the growing demand but also strengthen its position as a leading supplier in the global automotive market. The company's relentless focus on quality, innovation, and customer service sets it apart from its competitors and reinforces its commitment to excellence in every aspect of its operations.As the automotive industry continues to evolve and grow, XYZ Company remains dedicated to staying ahead of the curve and providing its customers with the best panting parts available. With its expanded production capacity and unwavering commitment to innovation, the company is well-prepared to meet the needs of its customers and contribute to the continued success of the automotive industry.In conclusion, XYZ Company's decision to expand its production capacity for panting parts is a significant step in meeting the increasing demand from the automotive market. With its focus on quality, innovation, and customer satisfaction, the company is poised to continue its success as a leading supplier of high-quality panting parts for vehicles around the world.

High-speed 3D Printing Factory: A Leader in OEM Manufacturing

Foxstar Fast 3D Print Factory Introduces Cutting-Edge Manufacturing SolutionsIn today's fast-paced world, businesses across various industries are constantly seeking efficient and precise manufacturing solutions to meet their diverse needs. Foxstar, a leading OEM fast 3D print factory, is committed to delivering superior precision and efficiency on every project. With a wide range of capabilities, including CNC machining, injection molding, sheet metal fabrication, and 3D printing, Foxstar serves multiple industries with a variety of materials and finish options, providing one-stop solutions for manufacturing needs.With a strong emphasis on innovation and technology, Foxstar Fast 3D Print Factory has established itself as a trusted partner for businesses looking to streamline their manufacturing processes and bring high-quality products to market. By leveraging the latest advancements in 3D printing technology, Foxstar is able to offer rapid prototyping and production capabilities, allowing companies to turn their ideas into reality in a fraction of the time compared to traditional manufacturing methods.One of the key advantages of working with Foxstar is its extensive suite of manufacturing capabilities. Whether a company requires precision CNC machining for complex components, large-scale production through injection molding, or rapid prototyping with 3D printing, Foxstar has the expertise and equipment to deliver high-quality results. Furthermore, the company's commitment to using a variety of materials and finish options ensures that each project is tailored to meet the unique requirements of its clients.Foxstar's strong customer focus and dedication to excellence are evident in its state-of-the-art facilities and team of experienced professionals. The company's team of engineers and technicians are equipped with the knowledge and skills to tackle the most challenging manufacturing projects, offering valuable insights and expertise to help clients achieve their goals. By establishing a collaborative approach with its clients, Foxstar ensures that every project is executed with the highest level of precision and attention to detail.In addition to its superior manufacturing capabilities, Foxstar Fast 3D Print Factory takes pride in its commitment to sustainability and environmental responsibility. The company utilizes advanced manufacturing techniques and materials that minimize waste and reduce the environmental impact of production processes. By embracing sustainable practices, Foxstar aims to not only meet the needs of its clients but also contribute to a more sustainable future for the manufacturing industry.With the global manufacturing landscape constantly evolving, Foxstar continues to stay ahead of the curve by investing in the latest technologies and expanding its capabilities. The company's dedication to research and development ensures that it remains at the forefront of innovation, offering its clients access to cutting-edge manufacturing solutions that are unmatched in the industry.As businesses look to adapt to changing market demands and remain competitive, Foxstar's comprehensive suite of manufacturing capabilities provides a strategic advantage. Whether it's rapid prototyping for product development, large-scale production for commercialization, or custom manufacturing for specialized components, Foxstar Fast 3D Print Factory is well-equipped to deliver results that exceed expectations.In conclusion, Foxstar's commitment to superior precision, efficiency, and innovation sets it apart as a leader in the manufacturing industry. With a diverse range of capabilities and a strong focus on customer satisfaction, the company is well-positioned to continue providing best-in-class solutions to businesses across various industries. As the manufacturing landscape continues to evolve, Foxstar remains dedicated to staying ahead of the curve and delivering cutting-edge manufacturing solutions that propel its clients towards success.

Top Quality Metal Fabrication Services for Your Project

Metal Fabrication Company Expands Services to Meet Growing Industry DemandsIn the world of manufacturing, precision and efficiency are key components to achieving success. This is why the Metal Fabrication Company, a leader in the industry, has expanded its services to offer a wide range of solutions to meet the growing demands of the market.Based in [location], Metal Fabrication Company has established itself as a go-to source for CNC machining, injection molding, sheet metal fabrication, 3D printing, and more. With a focus on delivering superior precision and efficiency on every project, the company has steadily built a reputation for providing high-quality, reliable solutions to a diverse range of industries.Through its dedication to innovation and customer satisfaction, Metal Fabrication Company has become a trusted partner for businesses in need of manufacturing services. Utilizing state-of-the-art equipment and advanced processes, the company has the ability to work with a variety of materials and finish options, providing one-stop solutions for manufacturing needs.One of the key strengths of Metal Fabrication Company is its extensive experience in serving multiple industries. From automotive and aerospace to healthcare and consumer goods, the company has a proven track record of delivering exceptional results across a wide spectrum of applications. With a team of skilled engineers and technicians, Metal Fabrication Company has the expertise to tackle even the most complex projects with confidence and precision.With the industry landscape evolving at a rapid pace, Metal Fabrication Company has recognized the need to adapt and expand its services to keep up with the changing demands of its customers. In response to this, the company has made significant investments in its capabilities, allowing it to offer a more comprehensive suite of manufacturing solutions to its clients.One of the most notable expansions for Metal Fabrication Company is its enhanced CNC machining capabilities. With the addition of new equipment and technologies, the company has significantly increased its capacity and efficiency in producing precision machined parts. This upgrade has allowed Metal Fabrication Company to take on larger and more complex projects, while maintaining the same high level of quality and accuracy that its clients have come to expect.In addition to its CNC machining enhancements, Metal Fabrication Company has also expanded its injection molding and sheet metal fabrication capabilities. By optimizing its processes and investing in new machinery, the company has streamlined its production operations, resulting in faster turnaround times and improved cost-effectiveness for its customers.Furthermore, Metal Fabrication Company has incorporated 3D printing into its service offerings, allowing for rapid prototyping and low-volume production of parts with complex geometries. This addition has proven to be a valuable asset for clients looking to quickly iterate and test new designs, and has positioned Metal Fabrication Company as a leader in additive manufacturing solutions.The comprehensive range of services offered by Metal Fabrication Company reflects its commitment to meeting the diverse needs of its customers. By providing a one-stop shop for manufacturing solutions, the company has positioned itself as a valuable partner for businesses in search of reliable, high-quality production services.As the industry continues to evolve, Metal Fabrication Company remains dedicated to staying at the forefront of manufacturing technology and innovation. The company's ongoing commitment to delivering superior precision and efficiency on every project has solidified its reputation as a trusted and reliable partner for businesses in need of cutting-edge manufacturing solutions.With its expanded capabilities and unwavering dedication to customer satisfaction, Metal Fabrication Company is well-equipped to meet the growing demands of the market and continue to provide exceptional results for its clients.

Small Batch Production Casting Companies for OEM Manufacturing

OEM Small Batch Production Casting Companies Boost Efficiency with Foxstar's One-Stop Manufacturing SolutionsIn today's fast-paced and competitive manufacturing industry, small batch production casting companies are constantly seeking ways to improve efficiency and precision in their manufacturing processes. One company that has been leading the way in delivering superior precision and efficiency on every project is Foxstar. With their comprehensive range of manufacturing services, including CNC machining, injection molding, sheet metal fabrication, 3D printing, and more, Foxstar has been providing one-stop solutions for manufacturing needs to small batch production casting companies across multiple industries.Foxstar's commitment to delivering high-quality, precision-engineered products has made them a trusted partner for small batch production casting companies looking to streamline their manufacturing processes. With their advanced CNC machining capabilities, Foxstar is able to produce complex parts with exceptional precision, allowing small batch production casting companies to achieve their desired specifications with ease. Injection molding services provided by Foxstar also enable small batch production casting companies to efficiently produce large volumes of parts with consistent quality, reducing production lead times and costs.Additionally, Foxstar's sheet metal fabrication services offer small batch production casting companies the flexibility to produce a wide range of components with varying complexities and sizes. Whether it's simple brackets or intricate enclosures, Foxstar's sheet metal fabrication capabilities ensure that small batch production casting companies can meet their customers' diverse manufacturing needs.Furthermore, Foxstar's 3D printing capabilities have revolutionized the way small batch production casting companies approach prototyping and low-volume production. With the ability to rapidly produce intricate and customized parts, 3D printing has become an essential tool for small batch production casting companies looking to bring new products to market quickly and cost-effectively.By offering a comprehensive suite of manufacturing services, Foxstar has become the go-to partner for small batch production casting companies seeking to optimize their production processes. Whether it's providing rapid prototyping services through 3D printing or delivering high-volume production runs through injection molding, Foxstar's one-stop manufacturing solutions have enabled small batch production casting companies to turn their design concepts into reality with unmatched precision and efficiency.In addition to their extensive range of manufacturing capabilities, Foxstar also offers a variety of materials and finish options to meet the specific requirements of small batch production casting companies. Whether it's producing parts in metal, plastic, or composite materials, Foxstar is dedicated to delivering high-quality products that meet the exacting standards of small batch production casting companies and their customers.As small batch production casting companies continue to face growing demands for faster turnaround times and higher-quality products, the need for reliable manufacturing partners like Foxstar has never been greater. By leveraging Foxstar's expertise and comprehensive range of manufacturing services, small batch production casting companies can confidently take on new projects and meet the evolving needs of their customers with ease.With a proven track record of delivering superior precision and efficiency on every project, Foxstar has solidified its position as a trusted partner for small batch production casting companies across multiple industries. Whether it's producing precision parts for the aerospace industry, medical devices, automotive components, or consumer electronics, Foxstar's one-stop manufacturing solutions have enabled small batch production casting companies to stay ahead of the competition and deliver exceptional products to their customers.In conclusion, the partnership between OEM small batch production casting companies and Foxstar's one-stop manufacturing solutions has ushered in a new era of efficiency and precision in the manufacturing industry. Through their advanced CNC machining, injection molding, sheet metal fabrication, 3D printing, and more, Foxstar has enabled small batch production casting companies to achieve their manufacturing goals with unmatched speed and quality. As the demand for high-quality, precision-engineered products continues to rise, small batch production casting companies can rely on Foxstar to deliver the manufacturing solutions they need to succeed in today's competitive marketplace.

Top Precision Stamping Manufacturers: Everything You Need to Know

Precision Stamping Manufacturers, a leading provider of precision manufacturing solutions, is continuing to expand its capabilities to better serve its customers. The company, which offers a wide range of services including CNC machining, injection molding, sheet metal fabrication, 3D printing, and more, is committed to delivering superior precision and efficiency on every project.With a focus on providing one-stop solutions for manufacturing needs, Precision Stamping Manufacturers has built a reputation for excellence in the industry. The company's commitment to delivering high-quality products, on-time delivery, and exceptional customer service has helped it become a trusted partner for a variety of industries.One of Precision Stamping Manufacturers' core competencies is precision stamping, which is a critical part of many manufacturing processes. The company's precision stamping capabilities enable it to create complex components with tight tolerances, making it an ideal partner for companies in the automotive, aerospace, electronics, and medical device industries, among others.In addition to precision stamping, Precision Stamping Manufacturers also offers a wide range of other manufacturing services. CNC machining, for example, allows the company to produce high-quality, precision parts with a high level of accuracy and repeatability. Injection molding, on the other hand, provides the ability to create complex plastic parts in a cost-effective and efficient manner.Sheet metal fabrication is another important part of Precision Stamping Manufacturers' service offerings. The company's expertise in this area allows it to produce a wide range of sheet metal components, from simple brackets to complex enclosures. And with the ability to offer 3D printing services, Precision Stamping Manufacturers can quickly produce prototypes and low-volume production parts with a high level of accuracy."We are proud to offer a comprehensive range of manufacturing services to our customers," said a company spokesperson. "From precision stamping to CNC machining to injection molding, we have the capabilities to meet a wide range of manufacturing needs. And with our commitment to quality and efficiency, our customers can trust that we will deliver superior products on time, every time."Precision Stamping Manufacturers serves multiple industries with a variety of materials and finish options, allowing its customers to get exactly what they need for their specific applications. Whether it's a small batch of parts made from stainless steel or a large production run of plastic components, the company has the expertise and resources to deliver top-quality results.The company's dedication to continuous improvement and investment in cutting-edge technology has allowed it to stay ahead of the curve in the fast-paced world of manufacturing. By staying up-to-date with the latest advancements in CNC machining, injection molding, sheet metal fabrication, and 3D printing, Precision Stamping Manufacturers is able to offer its customers the most advanced manufacturing solutions available."Our commitment to innovation and continuous improvement is what sets us apart in the industry," said the spokesperson. "We are always looking for new ways to improve our processes and expand our capabilities, so that we can continue to provide our customers with the best possible manufacturing solutions."As Precision Stamping Manufacturers continues to expand its capabilities and improve its processes, it remains focused on its core values of quality, integrity, and customer satisfaction. The company's dedication to delivering superior precision and efficiency on every project has earned it a reputation as a leader in the industry, and it is committed to continuing to raise the bar for excellence in manufacturing.With a wide range of manufacturing services, a commitment to continuous improvement, and a dedication to customer satisfaction, Precision Stamping Manufacturers is well-positioned to meet the needs of its customers and continue to be a trusted partner for years to come.

Get Instant Quotes for Sheet Metal Fabrication - The Ultimate Guide

Foxstar, a leading manufacturing company, is revolutionizing the industry with its innovative approach to precision and efficiency. With a wide range of capabilities, including CNC machining, injection molding, sheet metal fabrication, and 3D printing, Foxstar is dedicated to providing top-notch solutions for all manufacturing needs. Their commitment to excellence has made them a trusted partner for numerous industries, offering a variety of materials and finish options for a truly customized experience. With the launch of their new sheet metal instant quote tool, Foxstar is taking their commitment to customer convenience to the next level. This cutting-edge technology allows customers to receive instant quotes for their sheet metal fabrication needs, streamlining the process and saving valuable time. By simply entering their project specifications, customers can quickly and easily obtain a quote, giving them the information they need to make informed decisions about their manufacturing needs."We are thrilled to introduce our sheet metal instant quote tool, as it demonstrates our dedication to providing the best possible experience for our customers," said the company's spokesperson. "We understand that time is of the essence in the manufacturing industry, and this new tool is designed to make the process as efficient and seamless as possible."The sheet metal instant quote tool is just one of the many ways Foxstar is leading the pack in the manufacturing industry. Their commitment to utilizing the latest technologies and processes ensures that they are always at the forefront of innovation, providing their customers with the best possible solutions for their manufacturing needs.In addition to their sheet metal instant quote tool, Foxstar offers a wide range of services to meet the diverse needs of their customers. Their CNC machining capabilities allow for the production of high-precision parts, while their injection molding services provide cost-effective and efficient solutions for producing plastic parts. Their 3D printing services offer rapid prototyping and production, allowing for quick turnaround times and reduced costs.With their sheet metal fabrication capabilities, Foxstar can produce a wide range of parts and components, utilizing a variety of materials and finishes to meet the specific requirements of each project. From simple brackets to complex enclosures, they have the expertise and equipment to deliver outstanding results every time.What sets Foxstar apart from the competition is their comprehensive approach to manufacturing. As a one-stop solution provider, they are able to handle every aspect of a project, from design and prototyping to production and finishing. This integrated approach not only saves time and money, but also ensures that the final product meets the highest quality standards."We take great pride in our ability to offer a complete range of manufacturing services, all under one roof," said the company's spokesperson. "This allows us to control every aspect of the production process, ensuring that our customers receive top-quality results every time."With their state-of-the-art facilities and team of experienced professionals, Foxstar has established itself as a trusted partner for businesses across a wide range of industries. From aerospace and automotive to healthcare and consumer goods, they have the expertise and capabilities to meet the unique needs of each industry."We are dedicated to providing our customers with the best possible solutions for their manufacturing needs," said the company's spokesperson. "Whether it's a small prototype or a large-scale production run, we are committed to delivering superior results on every project."As Foxstar continues to push the boundaries of innovation in the manufacturing industry, their sheet metal instant quote tool is just the latest example of their commitment to excellence. By prioritizing precision, efficiency, and customer convenience, they are setting a new standard for manufacturing solutions, earning the trust and loyalty of businesses around the world.

Small Batch Production Casting Suppliers for OEMs: Find the Best Options

Foxstar, a leading manufacturing service provider, has announced its expansion into OEM small batch production casting, providing high-quality, efficient solutions for a range of industries. With a strong focus on precision and cost-effectiveness, Foxstar's small batch production casting services are set to deliver superior results for a diverse range of manufacturing needs.Utilizing state-of-the-art technology and a team of experienced professionals, Foxstar is able to offer small batch production casting services that meet the highest standards of quality and efficiency. The company's commitment to excellence is reflected in their wide range of manufacturing capabilities, including CNC machining, injection molding, sheet metal fabrication, 3D printing, and more. By providing one-stop solutions for all manufacturing needs, Foxstar is able to streamline the production process and deliver the best possible results for their clients.Small batch production casting is an essential process for many industries, allowing for the creation of high-quality, complex parts in a cost-effective and efficient manner. By expanding into this area of manufacturing, Foxstar is positioning itself as a valuable partner for businesses looking to produce small quantities of high-quality parts. Whether it's for automotive, aerospace, medical, or industrial applications, Foxstar's small batch production casting services are designed to meet the needs of a wide range of industries.Foxstar's small batch production casting services offer a number of key benefits for their clients. First and foremost, the company's dedication to precision ensures that every part produced meets the highest quality standards. This is achieved through the use of advanced technology and strict quality control measures, resulting in parts that are reliable and consistent. Additionally, Foxstar's small batch production casting services are highly cost-effective, offering a competitive alternative to traditional manufacturing methods. By leveraging their expertise in materials and finish options, Foxstar is able to deliver parts that meet the specific needs of their clients, with a focus on both performance and aesthetics.The expansion into small batch production casting represents a significant step forward for Foxstar, solidifying the company's position as a comprehensive manufacturing service provider. With the ability to deliver precision and efficiency on every project, Foxstar is well-equipped to meet the diverse needs of modern businesses. Whether it's the production of complex components, prototypes, or specialized parts, Foxstar's small batch production casting services are designed to offer a streamlined and cost-effective solution.In addition to small batch production casting, Foxstar continues to offer a wide range of manufacturing services, including CNC machining, injection molding, sheet metal fabrication, and 3D printing. This comprehensive approach to manufacturing allows the company to cater to a variety of industries, providing customized solutions for a diverse range of projects. By offering one-stop solutions for manufacturing needs, Foxstar is able to streamline the production process and provide a seamless experience for their clients.As Foxstar continues to expand its capabilities, the company remains committed to delivering superior results for their clients. With a focus on precision, efficiency, and cost-effectiveness, Foxstar's small batch production casting services are set to make a significant impact in the manufacturing industry. By offering high-quality solutions for a range of industries, Foxstar is well-positioned to meet the evolving needs of modern businesses, providing the tools and expertise needed to bring innovative ideas to life.In conclusion, Foxstar's expansion into small batch production casting represents a significant advancement for the company, solidifying their position as a leading manufacturing service provider. With a strong focus on precision and efficiency, Foxstar is well-equipped to meet the diverse needs of modern businesses, offering high-quality solutions for a wide range of industries. As the company continues to innovate and expand its capabilities, Foxstar's small batch production casting services are set to make a lasting impact in the manufacturing industry, providing a streamlined and cost-effective solution for businesses looking to produce high-quality parts.

Top Low Volume CNC Machining Exporters

Foxstar, a leading provider of precision manufacturing services, has been recognized as one of the best low volume CNC machining exporters in the industry. With a commitment to delivering superior precision and efficiency on every project, Foxstar offers a wide range of manufacturing solutions, including CNC machining, injection molding, sheet metal fabrication, and 3D printing.As a one-stop shop for all manufacturing needs, Foxstar serves multiple industries with a variety of materials and finish options. Whether it's a complex prototype or a small production run, Foxstar's team of experts ensures that each project is completed with the highest level of precision and quality.With a focus on low volume CNC machining, Foxstar has established itself as a top exporter in the industry. The company's state-of-the-art manufacturing facility is equipped with the latest CNC machines and advanced technology, allowing them to produce high-quality parts with tight tolerances and complex geometries.In addition to their CNC machining capabilities, Foxstar also offers injection molding services. Their expertise in molding various plastics and other materials allows them to produce high-quality parts with fast turnaround times. This, combined with their sheet metal fabrication and 3D printing capabilities, makes Foxstar a trusted partner for companies looking for low volume manufacturing solutions.What sets Foxstar apart from other low volume CNC machining exporters is their commitment to customer satisfaction. The company works closely with each client to understand their specific needs and requirements, ensuring that every project is completed to their exact specifications. With a focus on quality and efficiency, Foxstar strives to exceed customer expectations with every project they undertake.In addition to their manufacturing capabilities, Foxstar also offers a range of value-added services, including design assistance, prototyping, and assembly. This full-service approach allows customers to streamline their production process and reduce time to market, ultimately saving them time and money.Foxstar's commitment to excellence has earned them a reputation as one of the best low volume CNC machining exporters in the industry. Their dedication to quality, precision, and customer satisfaction sets them apart from the competition, making them a preferred partner for companies looking for reliable manufacturing solutions.With a focus on continuous improvement and innovation, Foxstar continues to invest in the latest technology and talent to stay ahead of the curve. Their ongoing commitment to excellence ensures that they will remain a top player in the industry for years to come.In conclusion, Foxstar's dedication to delivering superior precision and efficiency on every project has made them a top choice for companies looking for low volume CNC machining exporters. With a wide range of manufacturing capabilities and a full-service approach, Foxstar is well-equipped to handle the unique needs of their clients. Their commitment to quality, innovation, and customer satisfaction sets them apart from the competition, making them a trusted partner for companies across various industries.

Custom Metal Fabrication Services: Highly Skilled CNC Metal Fabrication Experts

CNC Metal Fabrication Company is a leading provider of precision metal fabrication and manufacturing services. With over 20 years of experience in the industry, the company has established itself as a trusted partner for a wide range of industries, including aerospace, automotive, medical, and defense.The company's state-of-the-art facility is equipped with the latest CNC machines and advanced tools, allowing them to deliver high-quality, custom metal fabrication solutions to meet their clients' specific requirements. Their team of skilled engineers and technicians is committed to providing innovative and cost-effective solutions, ensuring the highest level of precision and quality in every project.Recently, CNC Metal Fabrication has announced a significant expansion of their capabilities, which includes the addition of new CNC machines, increasing their production capacity and enhancing their ability to tackle complex and large-scale projects. This expansion is in response to the growing demand for their services and the company's commitment to staying at the forefront of metal fabrication technology.The company's dedication to quality and customer satisfaction has earned them a solid reputation in the industry. They have worked with a diverse portfolio of clients, delivering a wide range of products, from small precision components to large structural assemblies. Their expertise in materials such as aluminum, stainless steel, and exotic alloys allows them to meet the diverse needs of their clients with precision and efficiency.In addition to their manufacturing capabilities, CNC Metal Fabrication also offers engineering and design support to help clients optimize their designs for manufacturability, efficiency, and cost-effectiveness. This comprehensive approach ensures that clients receive the highest level of service and support throughout the entire fabrication process.One of the key strengths of the company is their commitment to innovation and continuous improvement. They invest in the latest technology and equipment, as well as ongoing training and development for their team, to ensure they remain at the forefront of the industry. This dedication to staying ahead of the curve enables them to offer cutting-edge solutions and exceed the expectations of their clients.Furthermore, CNC Metal Fabrication places a strong emphasis on quality control and precision. Their facility is equipped with advanced inspection and testing equipment to ensure that every product meets the highest standards of quality and accuracy. This commitment to excellence has earned the company ISO 9001 certification, further demonstrating their dedication to delivering superior products and services.As the demand for high-quality, precision metal fabrication continues to grow across various industries, CNC Metal Fabrication is well-positioned to meet the needs of their clients with their expanded capabilities and unwavering commitment to excellence. With a track record of delivering innovative solutions and exceptional customer service, the company is poised for continued success and growth in the industry.In conclusion, CNC Metal Fabrication Company's recent expansion and ongoing commitment to quality, innovation, and customer satisfaction solidify their position as a top provider of precision metal fabrication services. With a focus on leveraging the latest technology, a highly skilled team, and a dedication to exceeding client expectations, the company is well-equipped to meet the evolving needs of the industry and continue to be a leader in the field of metal fabrication.